Conductive Ink Market Analysis, Region, and Segment Forecasts, 2017-2025

|

| Conductive Ink Market |

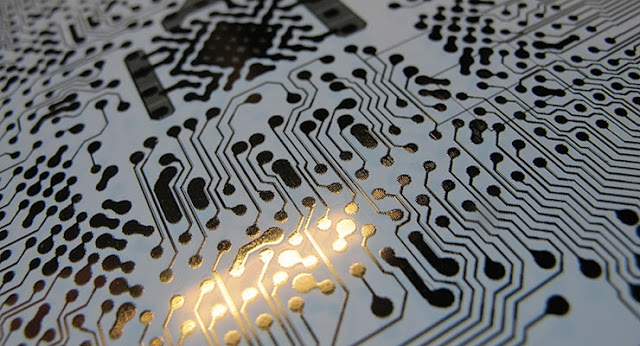

Environmental

regulations have been imposed by governments around the world to encourage

industries to reduce the amount of heavy materials used in any device by

replacing them with lightweight advanced materials. Along with this factor,

consumer preference for small and lightweight electronics has increased demand

for product miniaturisation in the consumer electronics industry. The use of

lightweight construction improves functional characteristics, reduces material

input, and saves energy. Conductive inks are efficient, effective, and

dependable, and they are widely used as a replacement for traditional wire and

circuit layouts to improve efficiency and reduce the weight of electronic

components.

The global Conductive

Inks Market is estimated to be valued at US$ 2,723.2 million in 2017 and is

expected to witness a CAGR of 6.2% during the forecast period (2017 – 2025).

Due to rising silver prices, there is a need for more cost-effective alternatives to silver-based conductive inks. Graphene is the most conductive form of carbon and is a single layer of carbon atoms. It can provide mechanical flexibility and high performance at a low cost, as well as aid in the corrosion protection of metals. Demand for conductive inks is anticipated to increase over the forecast period as a result of the expanding use of conductive inks in OLEDs, smart packaging, flexible displays, thin-film transistors, and smart textiles.. Recent advances in the printed electronics sector have allowed conductive inks to find applications in electronic and medical devices, which is expected to drive Magnesium Metal Market growth during the forecast period.

The high cost of silver conductive inks, combined with fluctuating conductive ink prices, is impeding Magnesium Metal Market growth. Because of its high conductivity, oxidation stability, and other unique properties, silver is one of the most widely used metals in the electronics industry. However, silver price fluctuations have resulted in a shift toward low-cost conductive metals such as copper, carbon, graphene, and aluminium. Because of the increased cost of silver, there is a need to either reduce or replace the use of expensive materials. However, the properties of the alternatives being offered are only marginally superior to those of silver. It is impossible to completely replace silver with alternative materials.

Comments

Post a Comment